I. Main feature

1. Intelligent Companion

This firefighting robot can be remotely controlled for firefighting, ensuring the personal safety of firefighters. It can also use intelligent follow-up control, allowing the firefighting robot to follow firefighters in real-time for emergency rescue and equipment transportation without the need for handheld remote control operation.

2.Expand applications

1) Quick detachable fire monitor, the robot can quickly disassemble the fire monitor when used as a transportation platform.

2) Water divider function: The robot is equipped with a water divider interface, which can directly connect fire hoses and water guns, improving fire extinguishing efficiency and reducing the operational intensity of firefighters.

3) Transport module:

Robots can be used to transport hand pumps and suction pipes to water intake points;

Robots can be used to transport hydraulic dismantling tools and quickly follow rescue personnel to the scene of accidents;

Robots can be used to transport mobile generator sets, mobile smoke exhaust fans, etc. to firefighting and rescue sites.

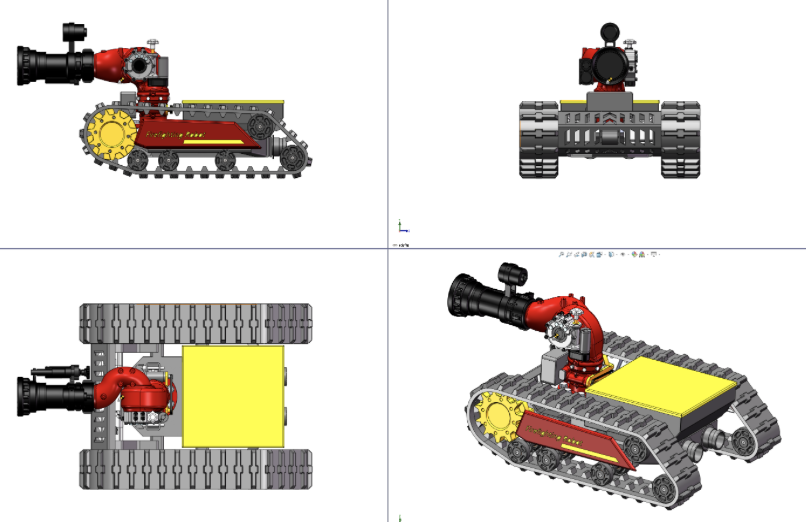

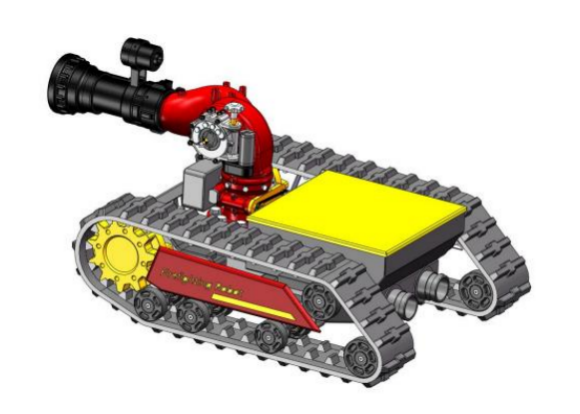

3.Trafficability

Adopting ATV off-road track chassis, the maximum climbing angle is 35 °, and the vertical obstacle crossing is ≥ 160mm.

4.Security

The robot is equipped with an active collision prevention and emergency stop control system to prevent damage to the firefighting robot and accidents that may cause injury to the operator or others due to misoperation.

5.Maintainability

The integrated skeleton water pipeline structure increases the maintenance space of the robot and makes inspection and maintenance more convenient.

6.Reliability

The motor, battery, and electronic control system are all from well-known brands, which can effectively ensure reliability.

II. Main technical parameters

1. Main performance parameters of the whole machine

1) Overall dimensions (mm): ≤ Length 1250 x Width 850 x Height 1200

2) Total weight (kg): ≤ 300

3) Drive form: ATV two wheel drive

4) Vertical obstacle crossing height (mm): ≥ 160

5) Climbing ability: ≥ 35°

6) Driving speed (km/h): 0-6 (continuously variable transmission)

7) Fire monitor flow rate @ range (L/s @ m): ≥ 50@65m

8) Range (h): 2 (uninterrupted driving)

9) Battery: Lithium ion battery

10) Remote control: Wireless display remote control, remote control distance ≥ 500m (open area)

11) 2 front lighting fixtures and 2 high-definition cameras at the front and rear.

2.Main Performance Parameters of Fire Cannon

1) Flow rate (L/s): ≥ 50

2) Maximum range (m): ≥ 65

3) Horizontal rotation angle (°): ± 30

4) Pitch angle (°): 20-80

5) Self swinging kinetic energy: One click self swinging

3.Water pipeline

1) Integrated skeleton water pipeline structure.

2) One DN80 fire monitor outlet and two KYK65 outlet ports (both with valves) are installed at the front end of the water pipeline.

3) Two KYK65 water supply interfaces are installed at the rear of the water pipeline.

4) Install robot self-protection sprinkler systems on both sides of the water pipeline.

The water pipeline is made of carbon steel, with surface electrophoresis and spray coating anti-corrosion treatment.

4.Electrical system

1) Remote control

2) Adopting a digital integrated remote control system, the remote controller can control all actions of the robot, including its movement, lighting, fire monitors, etc. And through the integrated remote control system of graphics and numbers, data transmission is carried out, making it convenient for operators to timely obtain the surrounding situation of the robot through the display screen.

3) Lighting fixtures

4) There are two 50W yellow and white LED lighting fixtures installed at the front of the robot.

5) Camera

6) Install one high-definition camera with a resolution of 1820 × 720 and a camera angle of 120 ° before and after the robot. Used for observing road conditions during the movement of firefighting robots, all video images can be transmitted in real-time to the rear remote control for display

![]()

![]()

light Camera

III. Overall standard

1) All instruments, operating switches, and the entire machine have nameplates that comply with the specifications.

2) The robot complies with the provisions of XF 892.1-2010 Fire Fighting Robots Part 1: General Technical Conditions.

3) All structural components, pipelines, etc. shall be welded firmly, polished smooth, and surface treated with anti-corrosion.

IV.Files and others

|

No.

|

Item

|

QTY

|

Remark

|

|

1

|

User & Maintenance Manual

|

1

|

|

|

2

|

Product certification

|

1

|

|

|

3

|

Tracking Service Card

|

1

|

|

|

4

|

A set robot tools

|

1

|

|

|

5

|

A set robot Easily-worn Parts

|

1

|

|

|

6

|

Handover checklist

|

1

|

|

Hot Tags: Robotics in Firefighting,advanced firefighting robot,fire fighting robot factory